WELCOME TO THE ERA OF DIGITAL RADIOGRAPHY

INNOVATIVE TECHNOLOGIES IN INDUSTRIAL RADIOGRAPHY

DR SYSTEMS is an international corporation specializing in developing, manufacturing and marketing direct Digital Radiography (DR) complexes for industrial inspection.

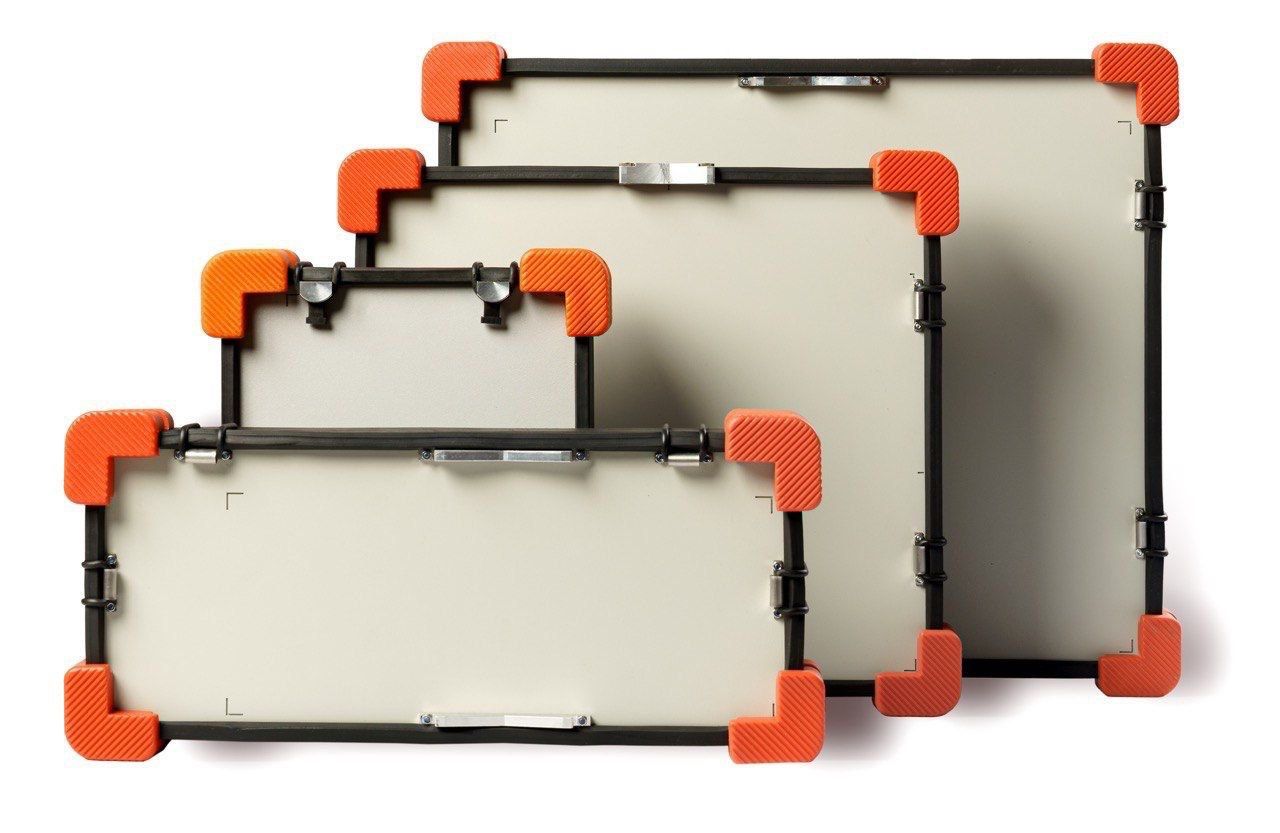

Portable Wireless Digital Radiography System with Flat-Panel Detector

SCANRAY® is a portable wireless digital radiography system available in several specifications with different pixel pitch and active area sizes to fit the exact needs in non-destructive testing: from welds and corrosion inspection in the oil and gas industry to the most demanding quality control of components in the shipbuilding, aerospace and military spheres. The complex is designed for detecting defects in the structure of various materials using the NDT method with X-ray or Gamma-ray sources. Radiographic images obtained by the detector are transmitted to the operator’s tablet or laptop in real time or accumulated in the internal detector’s memory for later downloading.

Customized solutions (for example, semi-automatic systems for extended longitudinal welds inspection of reservoirs, ship bottoms and other large-distance joints) and additional accessories for special needs (brackets, holders, tripods, manipulators, etc.) are available upon request.

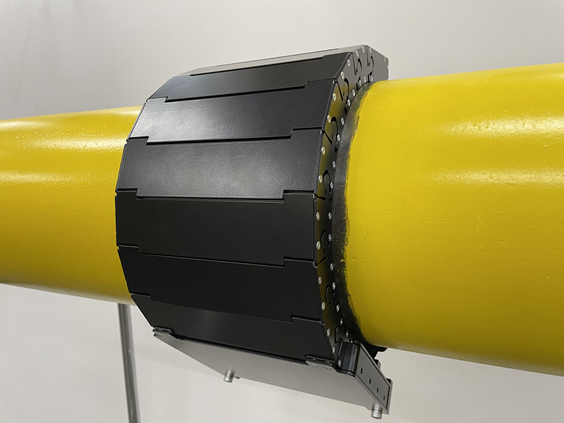

Flexible (Bendable) Portable Wireless Digital Radiography System

SCANRAY® F is a cutting-edge flexible (bendable) portable wireless DR system designed to revolutionize industrial radiographic testing of pipes and tanks. Traditionally, such inspections have relied on conventional X-ray films or flexible phosphoric imaging plates (computed radiography) due to their compatibility with curved surfaces. However, these methods pose challenges related to extended exposure times, intricate imaging processing procedures and dependence on consumables.

The SCANRAY® F complex addresses these limitations by offering a solution to eliminate image distortion on curved control objects, overcoming a significant drawback of ordinary digital flat-panel detectors. This innovative system not only provides a remedy to the inconvenience associated with conventional methods but also introduces a host of advanced features.

Digital Radiography System for Automatic Inspection of Annular Pipeline Welds

XPRESS-SCAN® represents a know-how mobile digital radiography system designed for automatic inspection of single- or double-wall pipe welds ranging from 159 mm (6 inches) and more in pipeline construction, maintenance or repair.

The complex aims to drastically enhance the speed of non-destructive testing, streamline operations and reduce the risk of human mistakes. Testing can be conducted immediately after welding, and instant results enable prompt adjustments to welding equipment settings should any defects be detected, ensuring they are not repeated in subsequent joints and thereby preventing project delays. Thanks to the minimal control time, the system provides a significant productivity boost in both onshore and offshore projects.

The availability of a convenient double-wall control scheme offers an optimal solution for situations where using a crawler is not feasible. Additionally, the system includes all necessary accessories and pre-installed DR-SOFT® software, equipped with a comprehensive toolkit for conducting various tasks within the realm of industrial radiographic inspection.

DR-SOFT

Software for Obtaining, Processing, Evaluating and Archiving Radiographic Images

The powerful and user-friendly software is designed for obtaining static and dynamic radiographic images from various devices, processing them for clear and easy interpretation, measuring linear dimensions, grey level and other digital image parameters, as well as archiving results in a database.

The software fully complies with the DICONDE standard ASTM E2339-21, allowing for carefully securing the data and preservation of additional information alongside images, such as material, thickness, pipe diameter, weld number, exposure parameters, date, time and geographical coordinates of the capture location.